Better performance & lower fuel costs

Improved existing methane advantage reducing CO2 by up to 50%

The reUp process consists of each component being stripped down to its original condition, cleaned, inspected, assembled, and tested. Our dedication to ensuring high standards are met follows the part out the door.

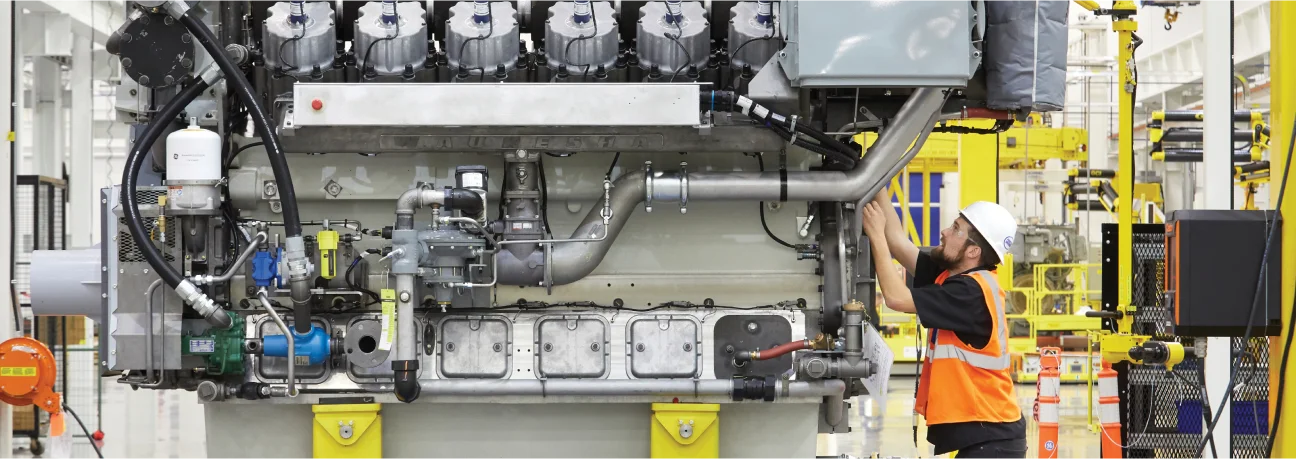

At Waukesha, an INNIO Group brand, we’re deeply committed to quality and meeting our customers’ needs. In addition to a highly trained quality assurance team, we also offer a variety of emergency reUp engines, long blocks, and short blocks at our one-million-square-foot design and manufacturing facility to support increasing uptime for our customers.

When Enstor Gas, LLC, needed to replace their lean-burn engines, Waukesha was there for them – with rebuilt VHP Series Five engines through our reUp Program. The result? Higher profitability and lower emissions.