Protecting Your Investment.

What is it?

Drill rig operating costs range from $200,000 to $800,000 per day depending on location, depth of drilling and numbers of wells.* With large investments on the line, producers and contractors need continuously running equipment that provides fuel cost savings while meeting emission standards.

How It Works

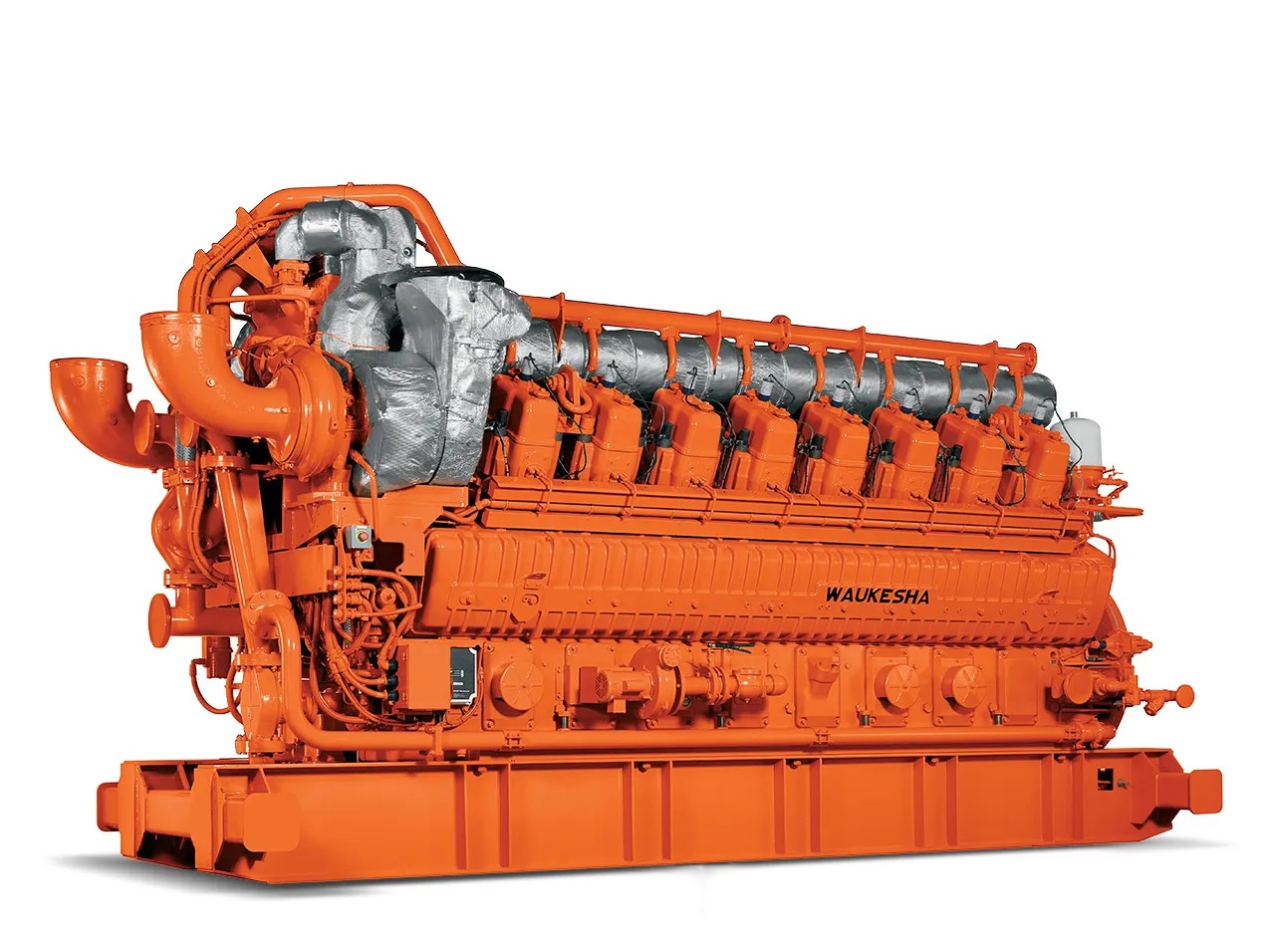

U.S. oil and gas production continues to rise. And while gas prices on average have decreased, diesel engines are still typically used to keep drill rigs running reliably. With government influences and an increased emphasis on sustainability, natural gas will continue to be an important resource and an efficient, profitable alternative to drilling rig power systems. The Waukesha mobileFLEX natural gas engine provides just that as a best-in-class low-emissions engine designed with oil production in mind.

The Waukesha Advantage

The Waukesha mobileFLEX engine runs on a wide variety of fuels, including LNG, CNG, propane and virtual pipeline gas – helping achieve up to 94% savings on fuel by using field gas vs. diesel while still achieving diesel-like performance. In addition, mobileFLEX engines can help you achieve up to 98% lower methane emissions and up to 40% lower CO2e vs. diesel-gas blend. The advantages are clear. Switching from diesel to a Waukesha mobileFLEX natural gas engine results in:

- Fuel cost savings

- A lower carbon footprint

- Quick starts – less than 10-second startup

- The ability to perform reliably in extreme heat or altitude (no derate up to 8,000 ft. at 100°F)

- Diesel-like performance without requiring load banks, ensuring optimal performance in multifuel oilfield power generation

- The ability to handle transients from 0 to 60% load with less than a 5% frequency drop

Mechanical Drive Engines

CASE STUDY

Waukesha teams with Ember for an “all-around win.”

The right engine for your project.

Improve production. Reduce emissions. Run smoother. Just call the Waukesha team, and we can help make it happen.